Special Machinery and Custom Automation Projects

Let’s design the machine you need!

Tailored Robotics & Custom Automation Projects

At Vulcan Automation, we excel at designing and delivering bespoke robotic systems for unique production challenges. From adapting to unconventional materials to integrating with legacy equipment, our custom machinery is engineered to meet your exact needs.

Below are examples of our special projects — each one a unique response to a specific industry challenge.

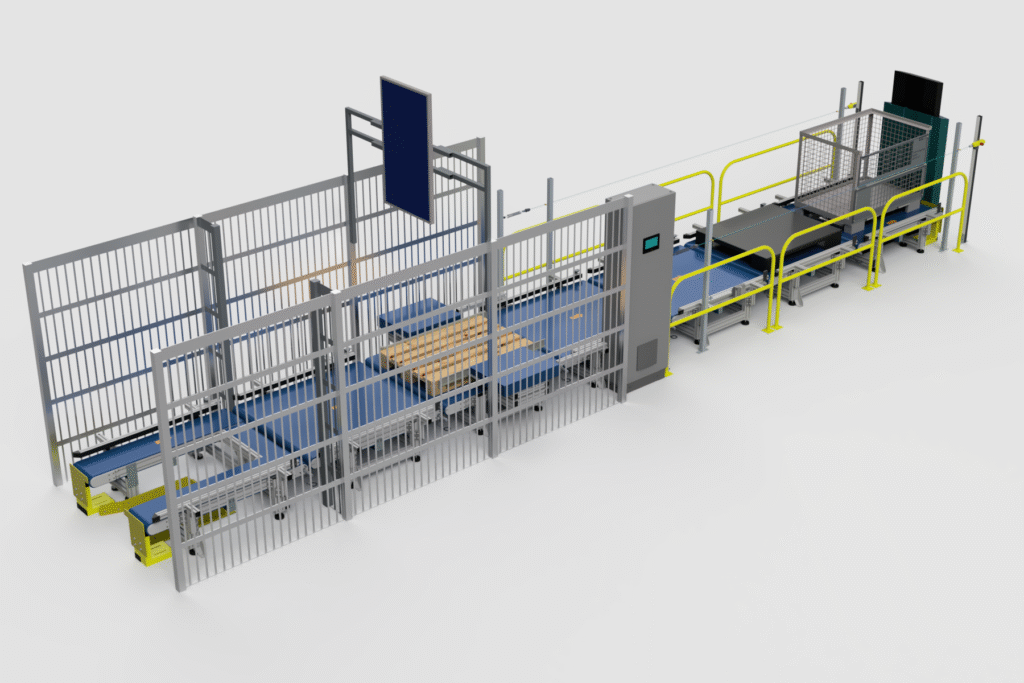

Smart Buffer Conveyor for Robot Forklifts

To bridge the gap between warehouse staff operations and the cycle time of autonomous AGILOX forklifts, Vulcan Automation developed a customized buffer conveyor solution.

Key Benefits:

- Smooths out timing mismatches between manual pallet loading and robotic transport.

- Eliminates unnecessary interaction between human operators and AMRs, reducing stoppages.

- Provides well-defined pick-up positions for robots, minimizing alignment time.

- Guides pedestrian forklifts to improve accuracy and pallet placement.

- Tracks pallet movement in real time and synchronizes individual pallet IDs with the robot system.

- Saves space

System Overview:

A fully autonomous, FIFO-driven, modular belt conveyor with 5 buffer positions plus dedicated loading and unloading points (5+2 design). The system includes intelligent sensors that track pallet location and share this data with the AGILOX AMRs.

Integration:

The conveyor integrates seamlessly with MES systems, transferring each pallet’s unique ID and real-time position to the AGILOX fleet. It supports centralized pallet alignment and enables safe, efficient handoff from manual operations to robotic transport.

Inline Screw-Tightening Robot Cell for Server Motherboards

To automate precision screw assembly in high-tech electronics manufacturing, Vulcan Automation developed a fully integrated robotic cell for tightening screws on server motherboards.

How It Works:

Motherboards enter the cell inline with the production flow, with screws pre-placed. A vision system detects the exact location of each screw, including any missing ones. A SCARA robot then tightens the screws to a recipe-defined torque value. The system ensures consistency, accuracy, and traceability.

Key Features:

- Vision-guided screw detection and validation

- SCARA robot ensures fast and precise screw tightening

- Torque control and measurement for every screw

- Automated feedback of torque data and motherboard ID to the MES system

- Flexible design — screw placement automation can be added if required

Benefits:

- Inline integration with minimal disruption to production flow

- Ensures quality compliance with real-time torque validation

- Reduces human error and improves traceability

Gluing tear-off pads and covers

A common task in the printing industry is the gluing of notepads in large numbers. This is a big burden on the operator, because of the monotony of the work. With Kerberos NS, you get consistent quality with less operator time. The hot-melt gluing method saves money and reduces environmental impact compared to using tapes.

The Kerberos NS robots can stick notepads, notebooks, point collectors, even all day, non-stop. The glued blocks can be placed either in a thin paper box or in a container. We can also place these paper boxes in another cardboard box and then place the finished boxes on a pallet.

Automated Polishing Cell for Refurbished Plastic Parts

Adaptive Robot Control

The core of the cell is a Universal Robots UR10e collaborative arm that performs the polishing process. The system intelligently detects when the polishing disc wears down and automatically adjusts the robot’s trajectory to maintain consistent surface pressure using a built-in PID controller. This ensures uniform polishing quality.Multi-Product Capability

The robot was configured to handle 8 different product types, each with complex surface geometries. During the project, traditional CAM software tools proved insufficient for precise path planning within the required cycle time. To overcome this, we developed a custom path generation environment that guarantees full surface coverage and allows for future expandability.Human-Machine Interface (HMI)

The system includes multi-level user interfaces accessible via touchscreen displays. Role-based access allows operators, maintenance staff, and supervisors to interact with the cell according to their responsibilities.MES Integration

The polishing cell is fully integrated with the factory MES system, enabling real-time process monitoring, traceability, and production feedback.Automated Bottle Handling and Packing Line

Vulcan Automation developed a modular inline system to automate the final processing steps of sealed plastic bottles. This fully integrated solution performs quality control, labeling, and robotic packing—designed to handle multiple bottle formats with high accuracy and flexibility.

Inline Quality Control

The system first checks the weight of each sealed bottle using a flow-scale. Following this, it performs a leak detection test by gently compressing the bottle to identify any pressure loss or sealing issues.

Labeling and Vision Verification

After passing the quality checks, each bottle is automatically labeled, and a vision system performs a camera-based verification to ensure the label is present, correctly placed, and legible.

Robotic Packing

A Universal Robots UR10e collaborative arm carefully picks the bottles and places them into plastic crates. The system supports three different bottle sizes, ensuring flexible operation without extensive mechanical changeovers.

Secondary Packing Option

The line includes a manual quick-change system that allows operators to switch between crate packing and the palletization of cardboard boxes, depending on production requirements.

Vertical Palletizing with Lift Support

To maximize vertical space usage, the robot is mounted on an OnRobot Lift100 actuator, enabling the system to build pallets up to 1.8 meters high—ideal for high-density logistics operations.

Tell us about your needs!