HMI for Palletizing

User friendly graphical interface designed to streamline palletizing robot applications.

What is HMI for Palletizing?

A palletizing robot application automates the process of stacking and organizing products onto pallets efficiently and safely. Our HMI makes palletizing robot programming easy and more simple.

HMI for Palletizing

- User friendly graphical user interface

- For virtually any robot

- Picking and placing logic stays on robot controller

Key features

- Possibility to interface with client’s MES

- Remote support option by Vulcan Automation

- Slip sheet handling

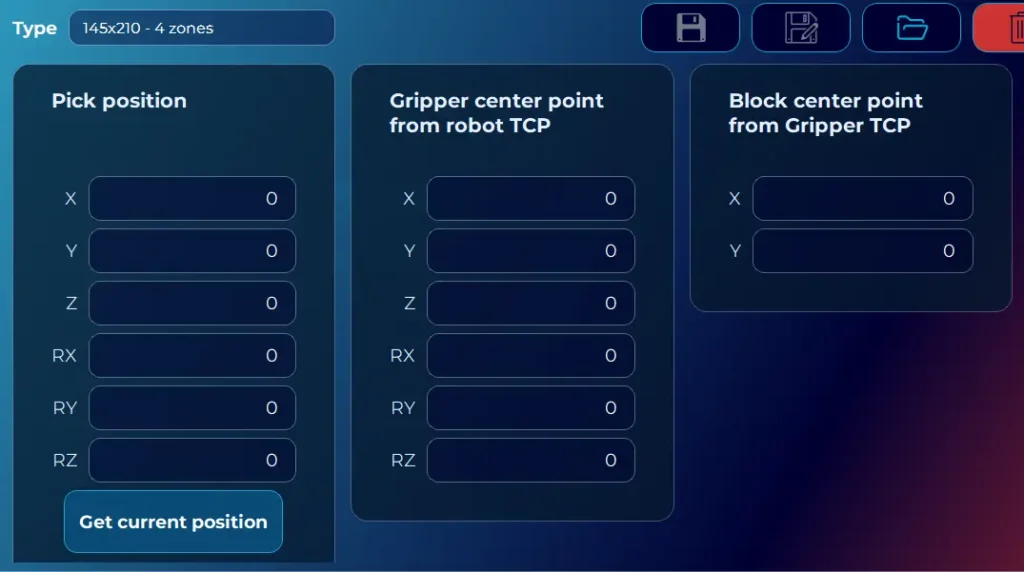

- Pick-up, placement position adjustable on screen

- Can be set to any layer

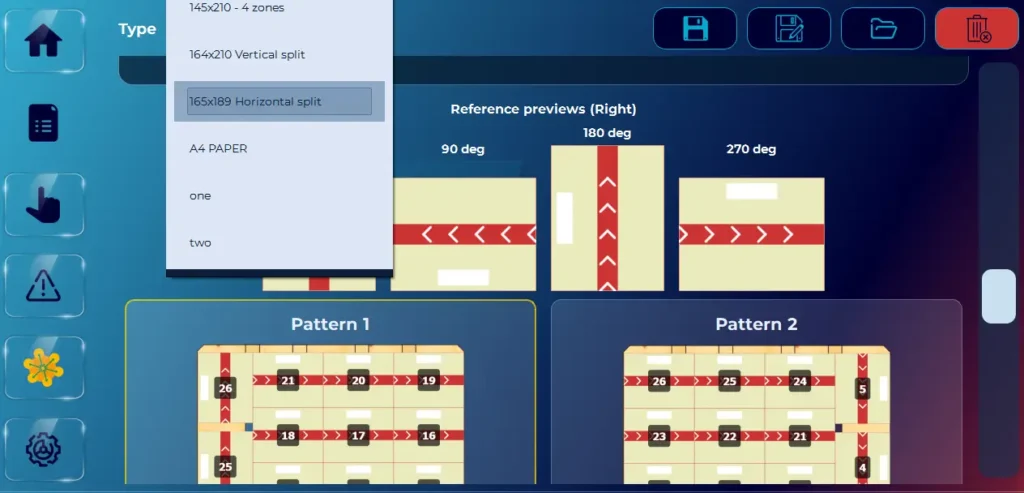

- Recipe handling: All parameters and patterns can be saved and loaded

- Operator and Admin levels. (Operator view can be customised.)

- Any lifting column can be used

Supported Pallets

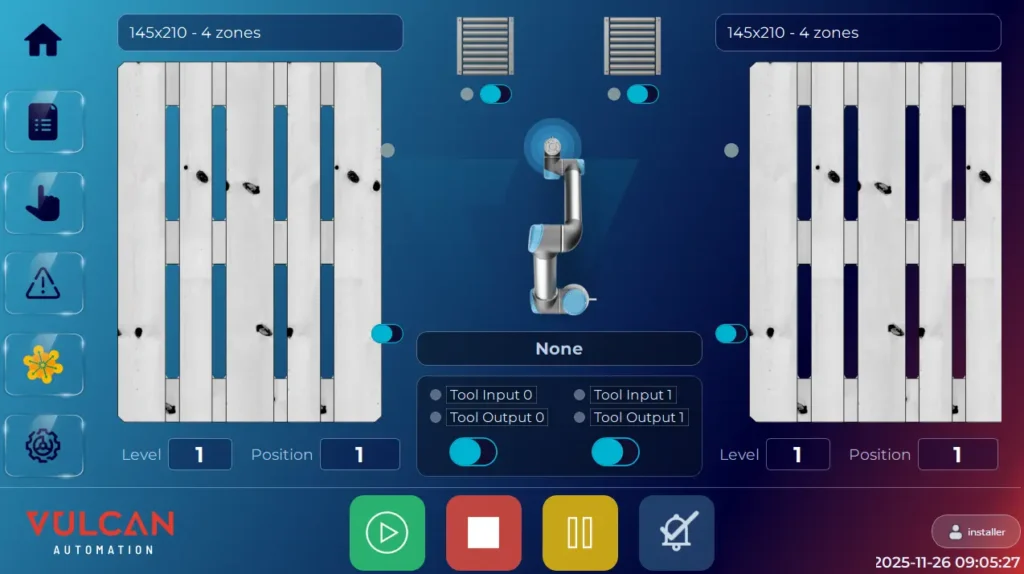

- 2 pallet places

- 1 or 2 input conveyors

Freely adjustable pallet sizes

- 800×1200

- 1200×800

- 1000×1200

- Or whatever is needed

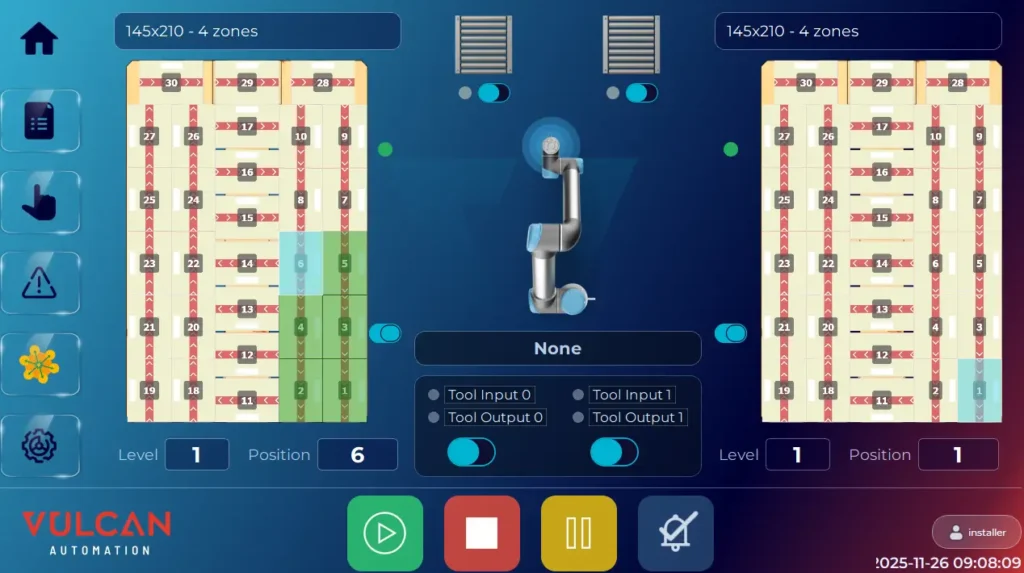

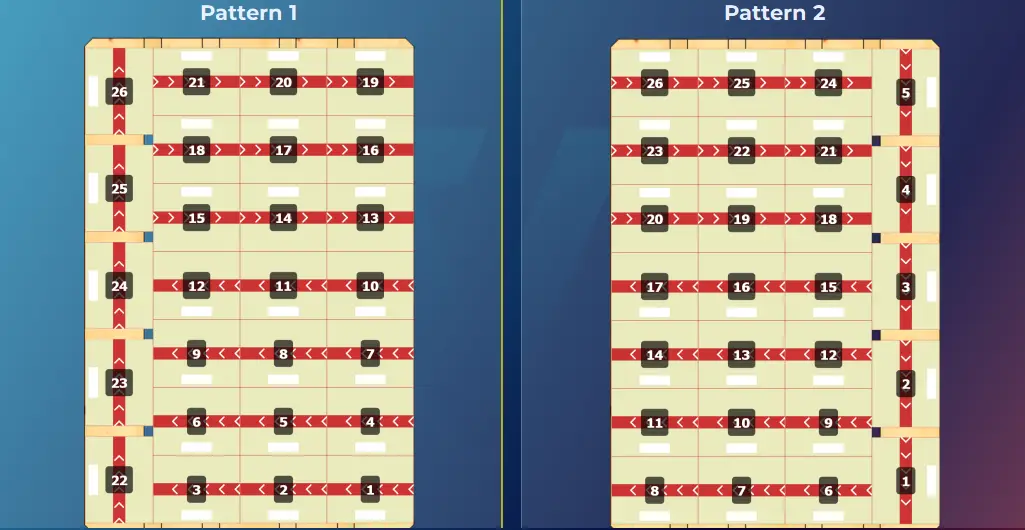

Palletizing Patterns

Automatic pallet pattern optimisation

- Box width x length

- Min. gap between boxes

- Overhang outside of pallet

- Enforcing overlaps possible

- Labels out function

- Automatic pattern mirroring for stable overlaps

- Manual pattern editing

- Easily add, delete, move and rotate boxes

Custom Gripping

Any gripper with custom

- Position offsets

- Tool IO labels on HMI

Any gripping method

- You can program it freely on the robot controller – the HMI just instructs the robot to grip

Solution expert

István Galambos

Sales Manager

+36-70-881 9279

istvan.galambos@vulcan-automation.com